solutions

based on experienceICS prides itself on problem solving, finding creative experienced-based solutions based on need.

save time and money with

Our integrated approach

For over twenty-five years ICS has built a comprehensive system of training, product development, and equipment installation to serve manufacturers who need industrial coatings.

testimonial

“I can’t believe it took us this long to use ICS for our paint needs. They streamlined our process in ways we didn’t know were possible.”

Jeff German, CEO

Standard Iron/Industrial Coating Services Case Study

Trane Pueblo Base frame paint quality upgrade

Standard Iron is a sub-contractor for Trane/ Ingersoll Rand in Pueblo Colorado. Standard Iron produces the base frames for Pueblo products. They produce base frames in varying sizes from 25-45 feet in length in Grand Island NE and Alexandria MN.

Industrial Coating Services, Inc. is the paint consultant and supplier to Standard Iron and Ingersoll Rand. Industrial Coatings Services, (ICS) provides technical training and engineering resources to the finishing area to include base metal preparation, application training and certification, application equipment and ongoing auditing for in service finish quality.

Standard iron started producing the frames in mid to late 2016 after reports of paint failures in the field at a warranty cost of $514,253. Once this issue was discovered, the frame production was moved over to Standard iron and ICS was asked to assist in putting a coating system together along with metal preparation to pass the Trane paint specification and assure finish quality.

Cost of warranty paint failures $ 514,253

Cost of upgrades and corrections $ 210,000

The following illustrations will detail how this was accomplished and how the finish quality is being maintained.

Before paint and process change:

After paint and process change:

Paint products used

- 2 component Hybrid Epoxy Primer

- 2 Component Urethane topcoat

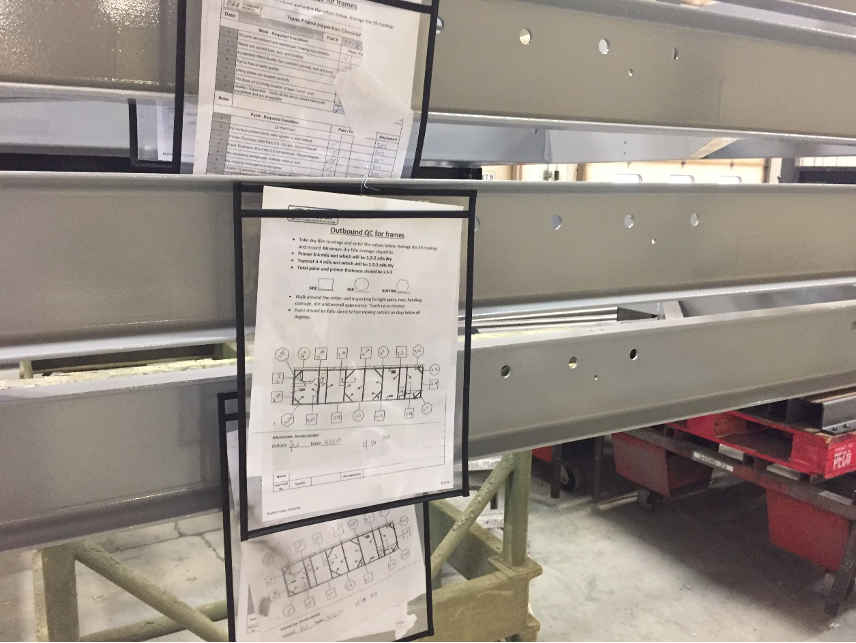

All Frames are QC’d for appearance and for proper thickness

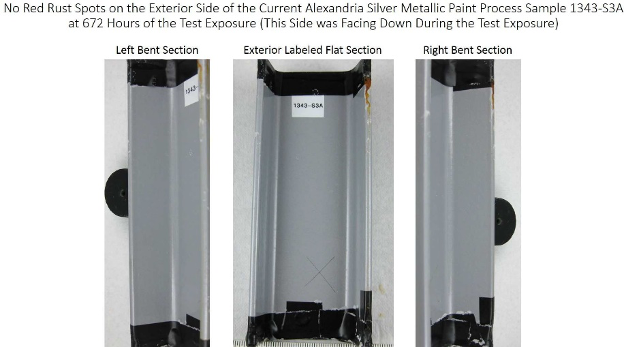

Paint performance

Testing was conducted on actual frame steel to Trane paint specification

Structural steel issue

Incoming steel is classified as structural steel. Structural steel is a low-grade inexpensive product. While structurally sound, the surface as delivered is rusty and full of scale.

A four-step process was implemented

- Foam acid application to removes scale

- Degrease and phosphate surface

- Rinse

- Zirconium seal

Final Fish

Once properly painted shipping damage issues were discovered and resolved with neoprene cradles to keep the base frames from hitting each other during transit.

Before

After

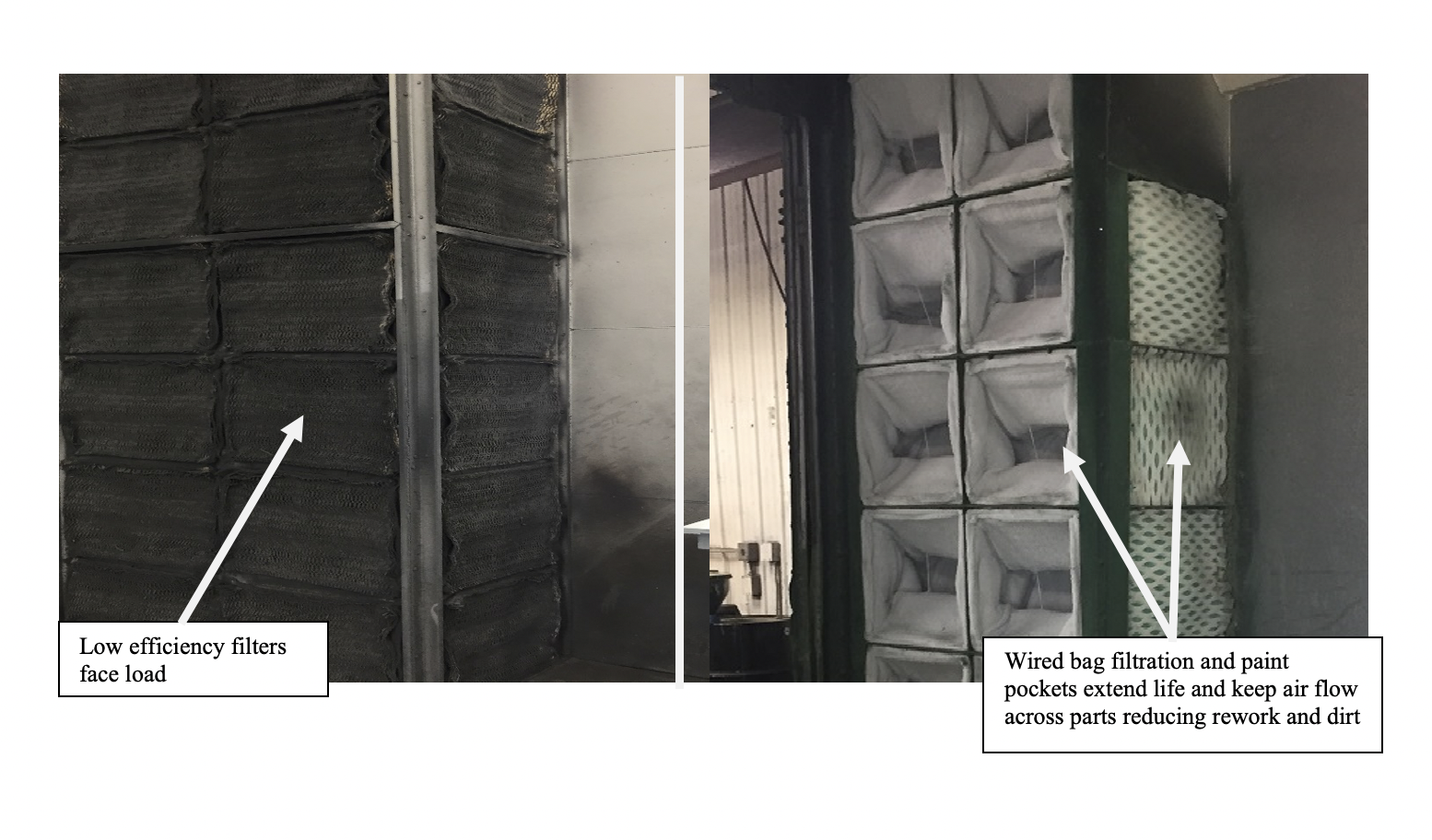

Paint booth performance upgrade

- Old style filtration on the left (Before) causes two problems

- Filters load and wrinkle causing paint particles to escape into the environment

- Air flow balance cannot be achieved because filters face load restricting air flow

- New more efficient filtration on the right (after) solves these two issues with Bag filters in the main plenum and pocket filters on front plenum. The bag filters increase surface area for longer life and better flow. Bag filters are wired around the edge to assure 99.8 particulate capture.

Frame presentation

Before: very difficult to paint because of highs and lows

Areas visible to end customer were the most difficult to paint

After

Class A surfaces presented at the optimal painting position

Paint mixing equipment upgrade Standard Iron Alexandria and Grand Island plants

Before: very difficult to paint because of highs and lows

Areas visible to end customer were the most difficult to paint

After

Class A surfaces presented at the optimal painting position

Let’s Talk

We welcome the opportunity to discuss your project needs.